Guide to Welding Automation – Discover Processes and Technology

Introduction to Welding Automation

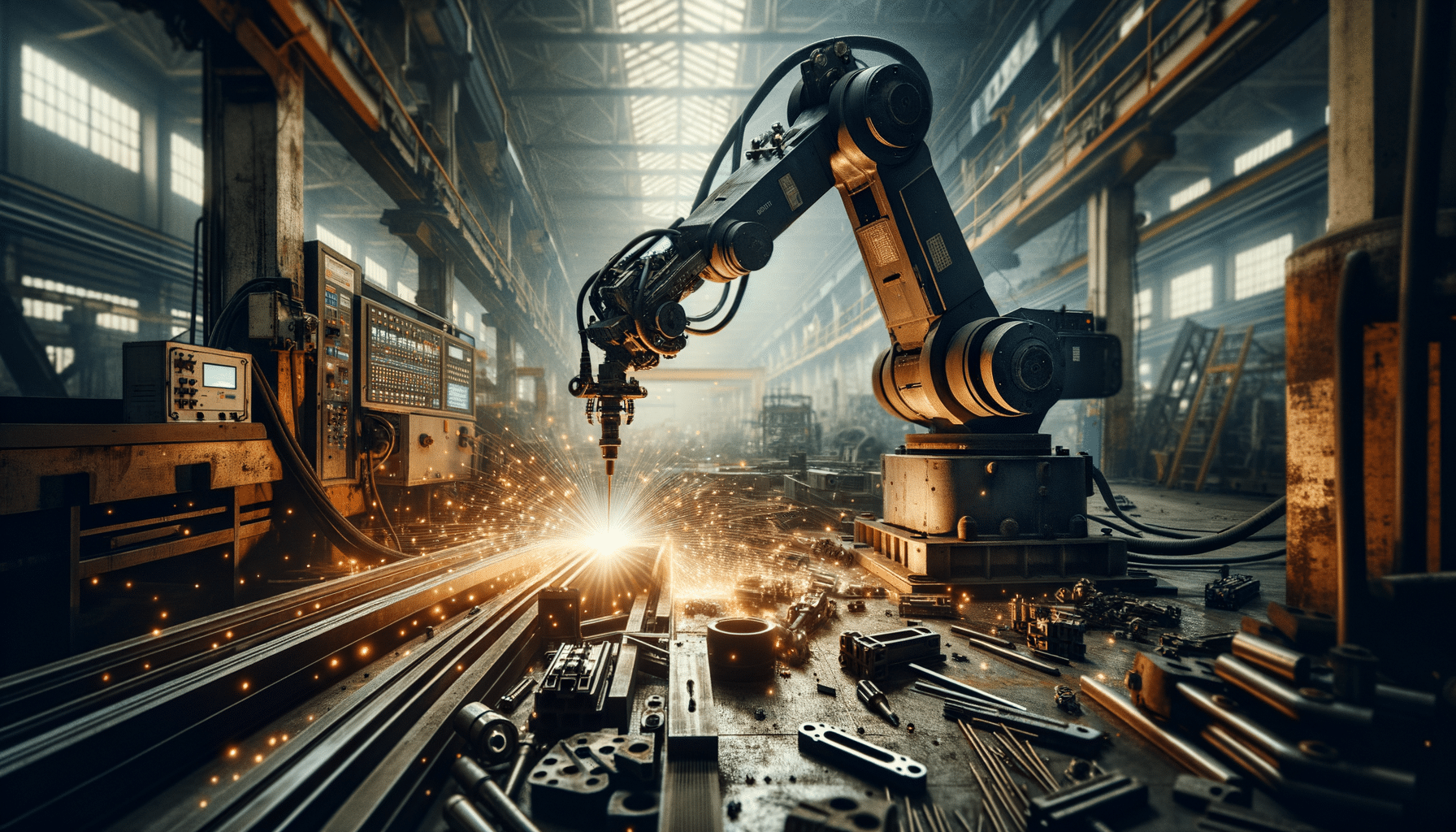

Welding automation is revolutionizing the manufacturing sector by enhancing efficiency, consistency, and safety. As industries seek to improve production capabilities, the demand for automated welding systems has grown significantly. Welding automation refers to the use of mechanized equipment to perform welding tasks, reducing the need for manual intervention. This shift not only speeds up the production process but also minimizes errors and improves the quality of welds. In this article, we will explore the different aspects of welding automation, including its benefits, various technologies, and the impact on the industry.

The Benefits of Welding Automation

Welding automation offers several advantages that make it a valuable investment for manufacturing companies. Firstly, it enhances productivity by allowing continuous operation without the fatigue and inconsistency associated with manual welding. Automated systems can work tirelessly, leading to increased throughput and reduced production times. Secondly, welding automation improves the quality of welds by ensuring precision and uniformity. Automated systems are programmed to follow exact specifications, resulting in consistent and high-quality welds. Additionally, automation enhances safety by minimizing the exposure of workers to hazardous welding environments. By reducing the need for manual labor, companies can also address labor shortages and allocate human resources to more strategic tasks.

- Increased productivity and throughput

- Consistent and high-quality welds

- Enhanced safety for workers

- Reduction in labor shortages

Types of Welding Automation

Welding automation can be categorized into two main types: semi-automated and fully automated systems. Semi-automated welding involves the use of automated equipment with human intervention for certain tasks. For example, an operator may control the positioning of the welding torch while the machine performs the welding process. This approach combines human expertise with automation to achieve efficient results. On the other hand, fully automated welding systems operate without any human intervention. They are equipped with advanced sensors and robotic arms that can perform complex welding tasks independently. These systems are ideal for high-volume production lines where speed and precision are crucial.

- Semi-automated welding: Combines human expertise with automation

- Fully automated welding: Operates independently with sensors and robotics

- Suitable for high-volume production lines

Technological Advancements in Welding Automation

Technological advancements have played a significant role in the evolution of welding automation. The integration of artificial intelligence (AI) and machine learning has enabled automated systems to adapt to varying conditions and optimize welding parameters in real-time. AI-powered systems can analyze data from sensors to make adjustments that enhance weld quality and efficiency. Additionally, the use of computer-aided design (CAD) and computer-aided manufacturing (CAM) software has streamlined the programming of automated welding systems. These tools allow engineers to simulate welding processes and optimize parameters before implementation, reducing the risk of errors and improving overall performance.

- AI and machine learning for real-time optimization

- CAD and CAM software for streamlined programming

- Enhanced weld quality and efficiency

The Impact of Welding Automation on the Industry

The adoption of welding automation has had a profound impact on the manufacturing industry. As companies strive to remain competitive in a global market, the ability to produce high-quality products efficiently is paramount. Welding automation has enabled manufacturers to reduce production costs while maintaining high standards of quality. This has led to increased competitiveness and the ability to meet the demands of a rapidly changing market. Furthermore, the implementation of automation has driven innovation in the industry, with companies investing in research and development to create more advanced and efficient systems. As a result, welding automation is not only transforming the way products are manufactured but also shaping the future of the industry.

- Reduced production costs

- Increased competitiveness

- Innovation and research in advanced systems

- Shaping the future of manufacturing

Conclusion

Welding automation is a game-changer for the manufacturing industry, offering numerous benefits that enhance productivity, quality, and safety. The integration of advanced technologies has further propelled the capabilities of automated systems, making them indispensable in modern production lines. As the industry continues to evolve, welding automation will play an increasingly vital role in meeting the demands of a competitive market. By investing in welding automation, companies can position themselves at the forefront of technological advancement and secure a prosperous future.