Guide to Welding Automation – Find More Info on Processes and Technology

Introduction to Welding Automation

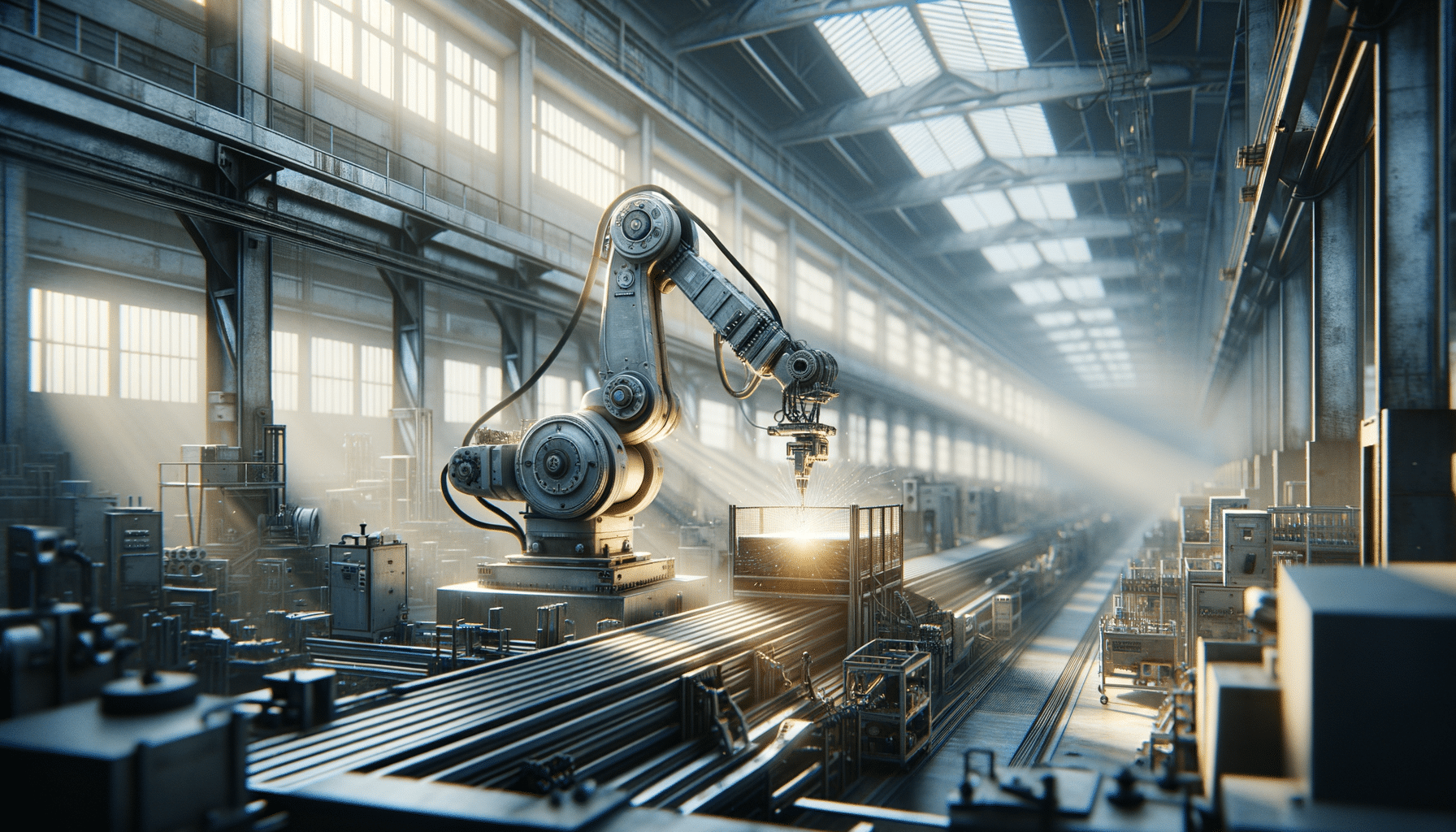

Welding automation is becoming increasingly significant in the industrial sector, driven by the demand for higher efficiency and precision. This advancement is not just a trend but a necessity as industries strive to meet the growing demands for quality and speed. Welding automation refers to the use of automated systems to perform welding operations, minimizing human intervention and enhancing productivity. In this guide, we will explore the different facets of welding automation, the technologies involved, and how they are revolutionizing manufacturing processes.

Types of Welding Automation Systems

Welding automation can be categorized into two primary types: semi-automatic and fully automatic systems. Semi-automatic welding involves human operators who handle the welding torch while the equipment controls the welding process. This type allows flexibility and is ideal for small batch productions. In contrast, fully automatic welding systems are designed to perform the entire welding process without human intervention. They are equipped with advanced robotics and sensors that ensure precision and consistency. These systems are highly suitable for large-scale productions, where speed and uniformity are crucial.

Both types of systems have their specific applications and benefits:

- Semi-automatic systems: Provide flexibility, suitable for custom jobs, and require skilled operators.

- Fully automatic systems: Offer high speed, precision, and are ideal for repetitive tasks in mass production.

By understanding these types, manufacturers can choose the right system that aligns with their production needs and goals.

Benefits of Welding Automation

Welding automation brings a myriad of benefits that significantly enhance the manufacturing process. One of the most notable advantages is improved efficiency. Automated systems can operate continuously without fatigue, leading to increased output. Additionally, welding automation ensures consistent quality by minimizing human errors, which are common in manual welding processes.

Moreover, the safety of workers is greatly enhanced. Automation reduces the need for human operators in hazardous environments, thus decreasing the risk of accidents and injuries. The precision of automated systems also reduces material waste, contributing to cost savings in the long run.

In summary, the key benefits of welding automation include:

- Increased production efficiency and output.

- Enhanced consistency and quality of welds.

- Improved safety for workers.

- Reduction in material waste and cost savings.

These benefits make welding automation an attractive investment for industries looking to optimize their production lines.

Technologies Behind Welding Automation

The technologies involved in welding automation are at the forefront of innovation. Robotics plays a pivotal role, with robotic arms being used to perform precise welding tasks. These robots are equipped with sensors and cameras to detect and adapt to changes in the work environment, ensuring optimal performance.

Another crucial technology is Computer Numerical Control (CNC), which allows for precise control over the welding process. CNC systems can be programmed to perform complex welding tasks with high accuracy, making them essential for industries requiring detailed work.

Furthermore, advancements in software have enabled real-time monitoring and control of welding processes. This allows operators to oversee operations remotely and make adjustments as needed, ensuring the highest quality standards are met.

Overall, the integration of robotics, CNC, and advanced software creates a robust framework that supports the efficient and precise execution of welding tasks.

Future Trends in Welding Automation

As technology continues to evolve, the future of welding automation looks promising with several emerging trends. One such trend is the increasing use of artificial intelligence (AI) and machine learning. These technologies enable systems to learn from data, improving their performance over time without human intervention.

Another trend is the development of collaborative robots, or cobots, which are designed to work alongside humans. These robots can take on repetitive tasks, allowing human workers to focus on more complex and creative aspects of production.

Additionally, the integration of the Internet of Things (IoT) is set to revolutionize welding automation. IoT enables real-time data collection and analysis, offering insights that can lead to further optimization of welding processes.

The future of welding automation is not just about replacing human labor but enhancing it, making the manufacturing process smarter, safer, and more efficient.